Exactly How Membrane Switches Add To the Longevity of Electronic Control Panels

Membrane layer buttons play a critical duty in boosting the durability of electronic control panels, primarily through their multi-layered building and construction which gives reliable security versus environmental elements such as moisture and dirt. The lack of moving parts dramatically lowers the likelihood of mechanical failures, making membrane layer switches ideal for requiring applications.

Definition of Membrane Layer Buttons

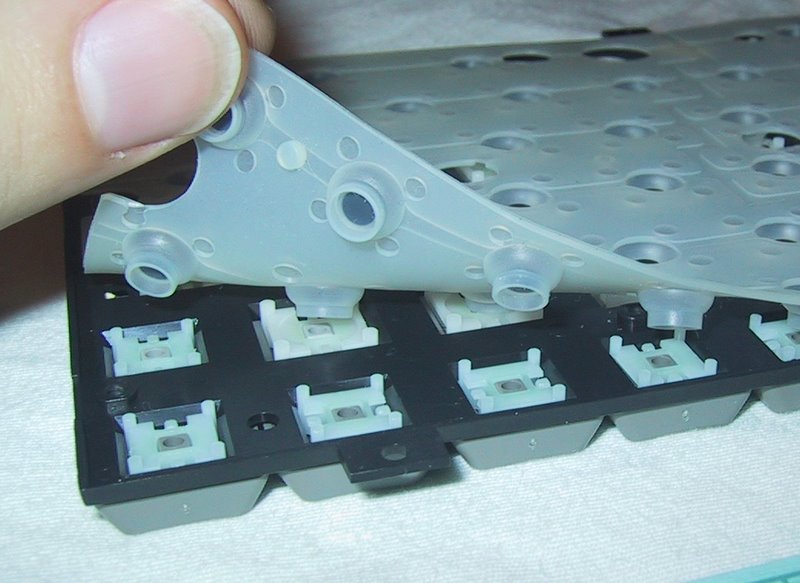

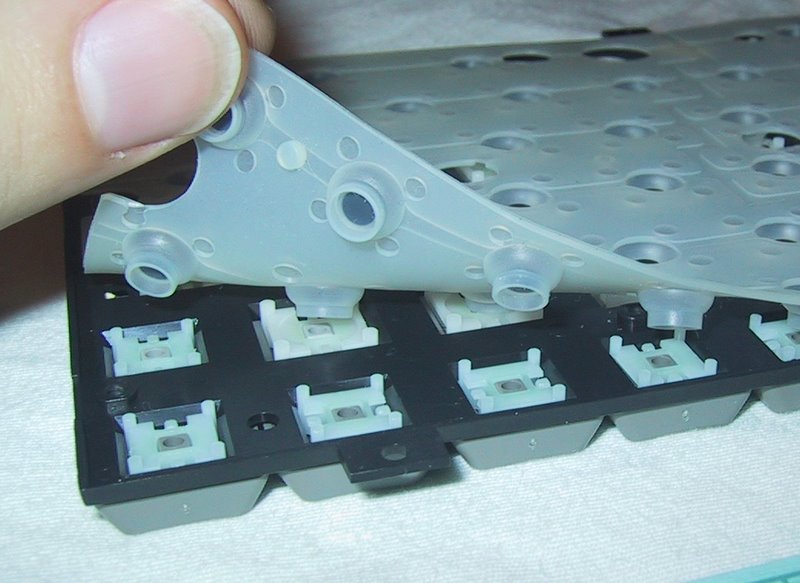

Membrane switches are created to be thin and light-weight, making them ideal for applications where space is limited. They can be produced in different forms, dimensions, and shades, offering versatility in design that fulfills aesthetic and practical requirements. In addition, membrane layer buttons can integrate numerous innovations, such as responsive comments and LED indications, boosting customer experience.

Because of their building, membrane layer buttons are usually resistant to dust, wetness, and general wear, adding to their toughness in requiring environments. Their seamless design not just facilitates simple cleansing yet also reduces the danger of mechanical failure, making them a favored option for producers seeking reputable individual interfaces in their electronic control panels.

Protection Against Environmental Factors

The design of membrane layer switches over inherently offers a level of defense versus different environmental factors, which is vital for preserving performance in tough conditions - Membrane Switch. These buttons are commonly created with layers of versatile materials that shield internal parts from wetness, dust, and impurities. By enveloping the wiring, membrane switches decrease the danger of short circuits and deterioration, which can substantially hinder performance

Moreover, the usage of robust adhesives and sealers during manufacturing boosts their resistance to ecological difficulties. Membrane layer switches can endure direct exposure to chemicals and solvents, making them ideal for industries such as food handling and health care, where hygiene and sanitation are critical. Their smooth surface area style also prevents the build-up of dirt and germs, assisting in simpler cleansing and maintenance.

Temperature level fluctuations are one more ecological concern, and membrane layer switches are engineered to operate efficiently throughout a variety of temperatures (Membrane Switch). This flexibility ensures that control panels continue to be operational in various setups, from industrial atmospheres to consumer electronics

Effect On User Interaction

Individual communication with digital control panels is considerably affected by the design and performance of membrane layer buttons. These buttons provide a responsive interface that improves the general customer experience, enabling intuitive navigation and control. Their receptive nature makes certain that users receive instant comments upon activation, which is critical for jobs needing precision and effectiveness.

In addition, the smooth surface area of membrane layer switches over facilitates easy cleaning and maintenance, promoting user confidence in the integrity of the interface. This tidiness is especially crucial in atmospheres where health is paramount, such as medical or food processing settings. Additionally, the portable and light-weight layout of membrane changes adds to the visual charm of control panels, encouraging user involvement via a modern-day and streamlined look.

Additionally, the integration of aesthetic components, such as published icons and backlighting, helps customers promptly determine features, reducing the finding out contour connected with new tools. As an outcome, users can operate gadgets much more effectively, leading to raised efficiency and complete satisfaction. In summary, membrane layer switches play a pivotal duty in improving customer communication by combining capability, visual appeals, and convenience of use, ultimately causing improved functional effectiveness.

Layout Versatility and Customization

Style versatility and personalization are essential elements of membrane switches, allowing makers to customize digital control panels to particular applications and customer demands. This adaptability enables for the assimilation of different design aspects, such as colors, graphics, and structures, which can boost the visual allure and customer interaction of the control panel.

Membrane buttons can be customized visit homepage in shapes and size, accommodating a large range of tools and applications, from industrial equipment to consumer electronic devices. This adaptability ensures that makers can develop intuitive interfaces that line up with customer assumptions and operational needs. Additionally, the capability to integrate special functions such as backlighting or responsive comments better boosts usability, permitting a much more interactive experience.

In addition, the manufacturing procedure for membrane changes supports the rapid prototyping of layouts, making it possible for suppliers to iterate and fine-tune their concepts promptly. This capability not just speeds up the advancement timeline however also makes certain that the final product meets certain practical and aesthetic standards.

Cost-Effectiveness and Long Life

Cost-effectiveness and durability are substantial advantages of membrane layer switches, making them an attractive alternative for suppliers and end-users alike. These switches are normally more economical to produce than standard mechanical switches, mainly as a result of their simplified production procedures and the reduced number of elements called for. This cost benefit extends not only to initial manufacturing but also to long-term operational costs, as membrane look these up layer switches typically need much less maintenance and have a lower failure rate.

Moreover, the long life of membrane layer switches adds to their overall value. Built from resilient products, they are immune to ecological variables such as moisture, dirt, and chemicals, which can lead to premature wear in other switch types. The lack of moving components lessens mechanical failure, allowing membrane layer changes to maintain performance over prolonged durations.

This resilience is particularly useful in applications calling for consistent performance under requiring conditions, such as clinical gadgets and industrial devices. Inevitably, the combination of cost-effectiveness and durability makes membrane switches a visit our website financially practical choice for producers, offering trustworthy services that endure the test of time while maximizing financial considerations.

Final Thought

Finally, membrane switches significantly improve the longevity of electronic control panels with their durable building and construction and protective features. By properly shielding circuitry from ecological dangers and decreasing the danger of mechanical failure, these switches ensure constant performance sought after applications. The smooth style promotes hygiene and simplicity of upkeep, while modification alternatives make it possible for customized remedies for different demands. In general, membrane switches represent a reputable and economical choice for enhancing the durability and performance of electronic control systems.